- Effects

- Details

- Related

Effect

Details

why we need coir fiber press baler machine for recycling?

There are many benefits to using a coir fiber baler to recycle coir fiber:

1. Improve the recycling efficiency of coir fiber

2. Save a lot of manual labour cost

3. Convenient transportation

4. Reduce the waste of coir fiber in the recycling process

The above can greatly reduce the cost of customers, improve the business income of customers, and effectively help customers expand the existing business scale.

TCM coir fiber baler

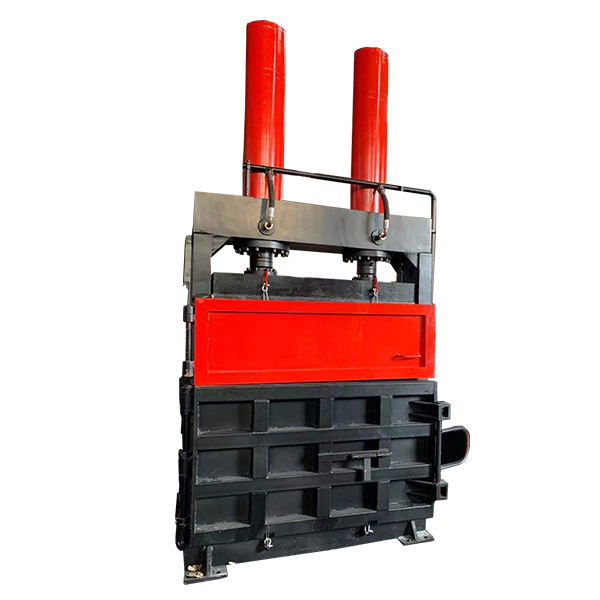

Coconut shell fiber is very fluffy, there is no bite force between each other, after being compressed by the baler, it will crack, so the package after packing needs to be strapped or steel wire for easy preservation.

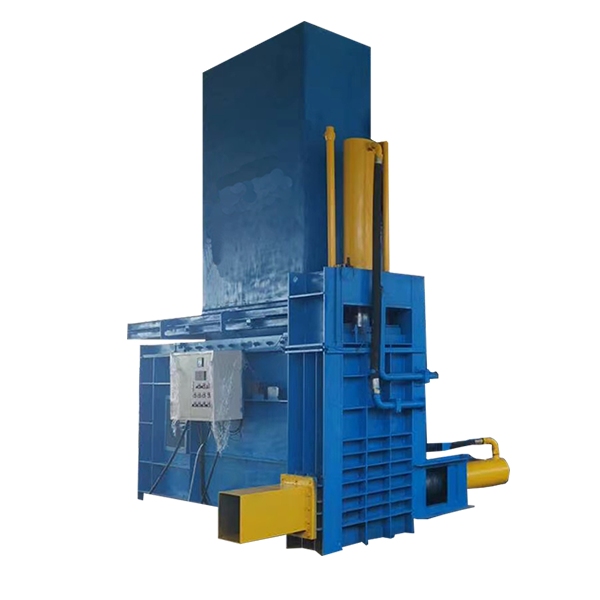

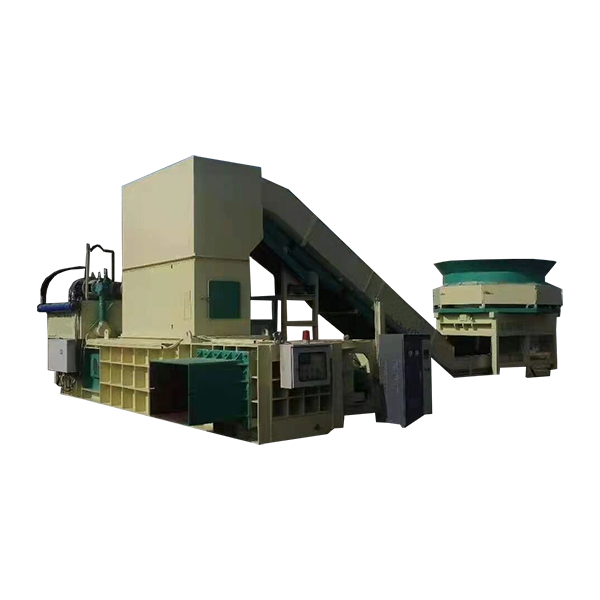

Our company produces two kinds of special packers for coconut shell fiber, which are DD series and HPA series. DD series baler adopts vertical structure and manual binding, while HPA series is full-automatic baler, conveyor feeding, machine automatic packing, and automatic binding with steel wire. The whole packing process is controlled by PLC, which realizes real full automation.

Advantages of DD series packing machine

1. High cost performance

2. The structure is simple, the work is stable, and it is not easy to break down

3. Convenient maintenance

Advantages of HPAC series coconut fiber baler

1. Automatic binding, no need of manual

2. Labor saving

3. Automatic feeding, high output